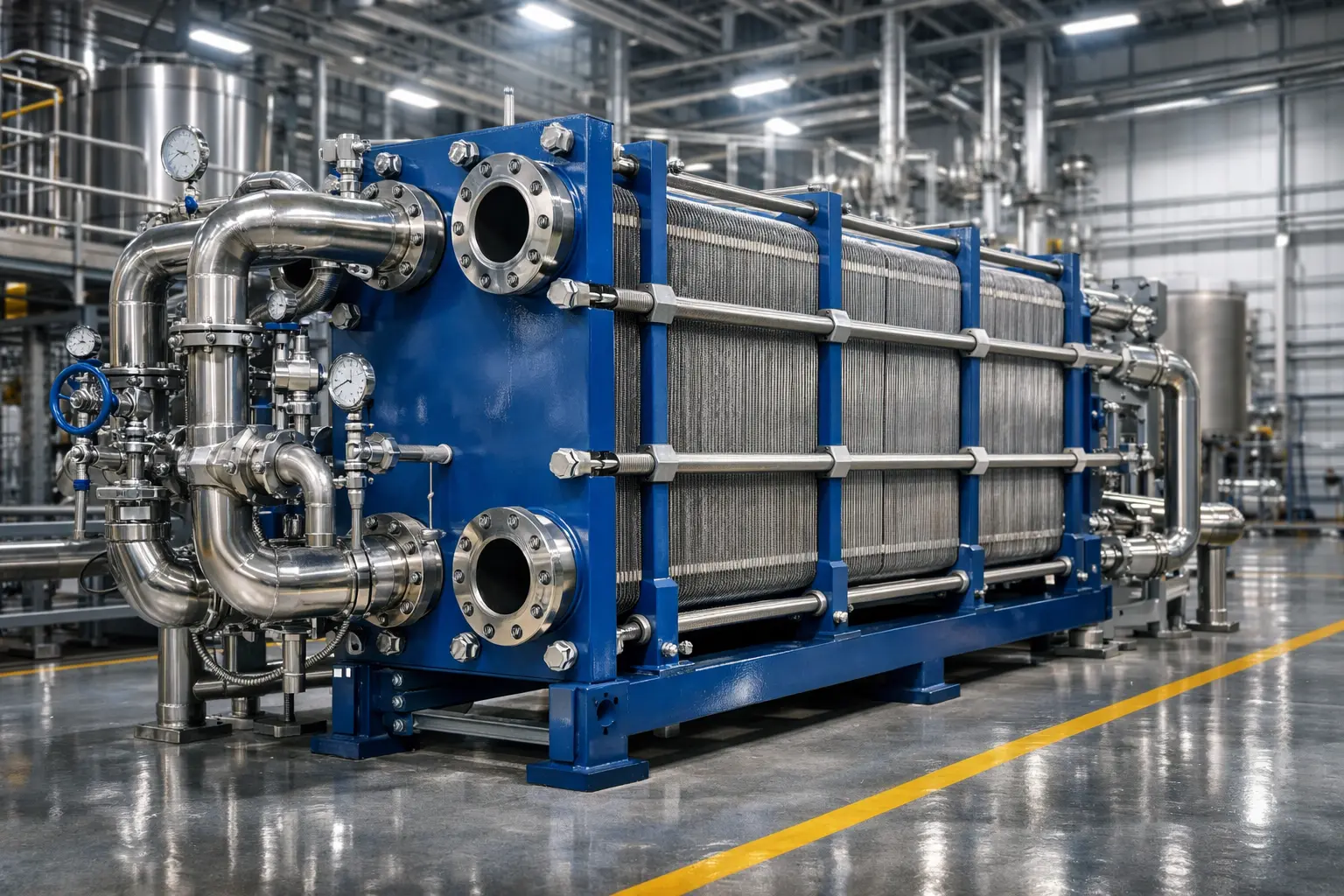

A welded plate heat exchanger is designed for industrial environments where high pressure, elevated temperature, and aggressive fluids make conventional gasketed systems unsuitable. In demanding applications such as chemical processing, refinery operations, ammonia refrigeration, and energy plants, a properly engineered welded plate and frame heat exchanger ensures safety, durability, and long-term thermal efficiency.

Unlike traditional units that rely fully on elastomer gaskets, a semi welded plate heat exchanger or fully welded system eliminates leak risks in critical zones by laser welding selected channels. Each welded plate is manufactured to withstand mechanical stress, corrosion exposure, and continuous-duty operation. This makes the welded heat exchanger an ideal solution for industries where operational reliability directly impacts productivity and safety.

This guide explains working principles, construction types, design benefits, industrial applications, selection criteria, and maintenance strategy — written in a practical, real-world format for plant engineers and industrial buyers.

What Is a Welded Plate Heat Exchanger?

A welded plate heat exchanger uses corrugated metal plates that are welded together instead of being fully gasket-sealed. Welding enhances mechanical strength and prevents leakage when handling:

- Ammonia and refrigerants

- High-pressure steam

- Aggressive chemicals

- Hydrocarbons

- High-temperature process fluids

In a typical welded plate and frame heat exchanger, the plates are welded in pairs to create cassettes. These welded cassettes are then assembled within a frame structure, allowing one side to remain gasketed for serviceability while the other side remains welded for safety.

This hybrid approach combines efficiency with durability.

Types of Welded Plate Heat Exchangers

Industrial systems are available in multiple configurations depending on process conditions.

1. Fully Welded Plate Heat Exchanger

- No gaskets between plates

- Designed for extreme pressure and temperature

- Suitable for refinery and petrochemical plants

2. Semi Welded Plate Heat Exchanger

- Plates welded in pairs

- One side gasketed for maintenance

- Common in ammonia refrigeration and chemical plants

3. Welded Plate and Frame Heat Exchanger

- Frame-supported structure

- Expandable design

- Easier inspection compared to fully welded block types

Each configuration balances maintenance accessibility with operational strength.

For industrial-grade options, explore Welded Plate Heat Exchangers and Semi-Welded Plate Heat Exchangers.

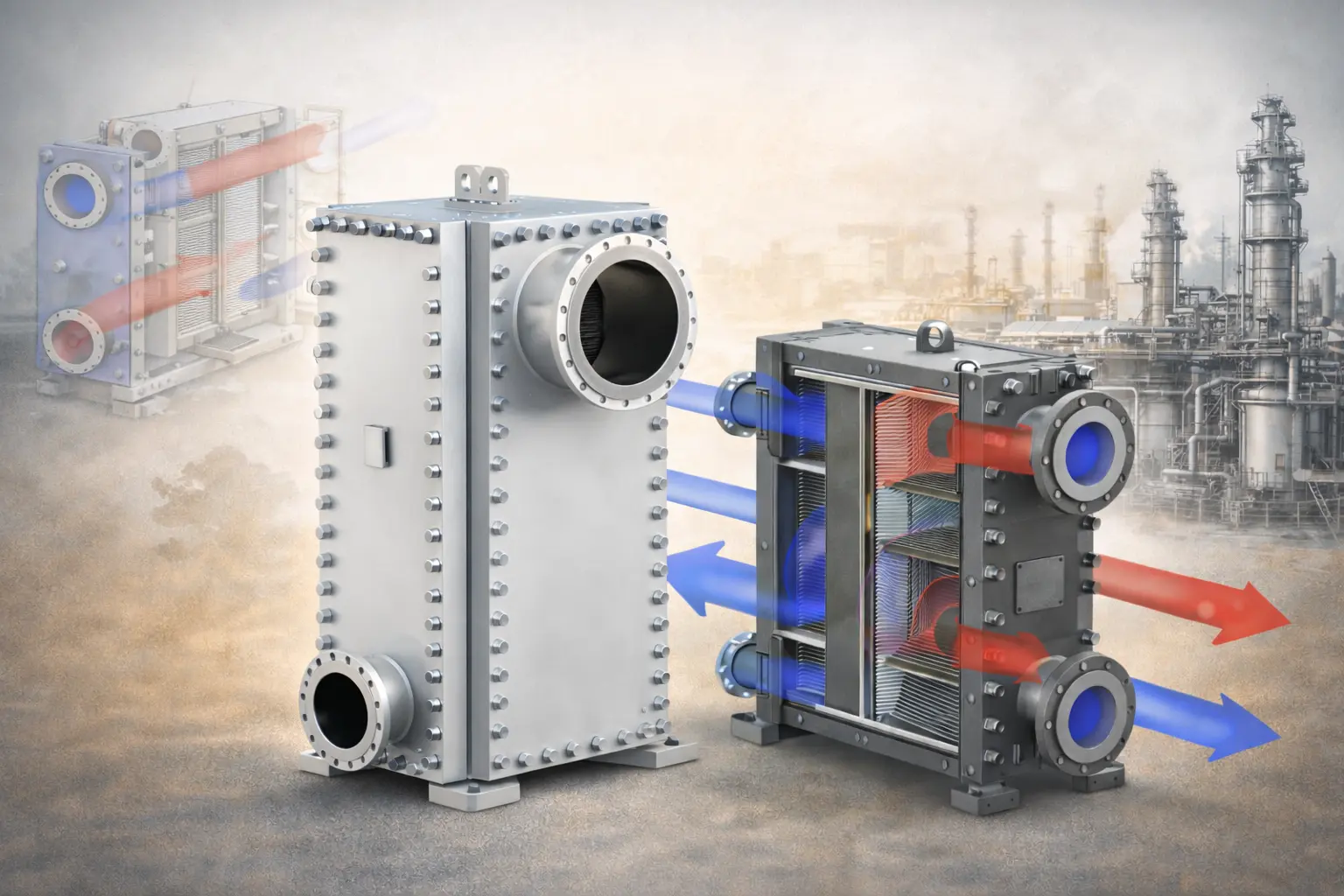

How a Welded Heat Exchanger Works

The working principle remains similar to other plate-based systems:

- Fluids enter alternate channels.

- Corrugated plates increase turbulence.

- Heat transfers across thin metal walls.

- Fluids exit separately without mixing.

The difference lies in structural integrity. A welded plate assembly withstands higher mechanical stress compared to gasket-only systems.

Because of the compact design and high surface turbulence, these systems offer excellent heat transfer coefficients while maintaining a small footprint.

Why Choose a Semi Welded Plate Heat Exchanger?

In applications involving ammonia or corrosive media, elastomer gaskets may degrade quickly. A semi welded plate heat exchanger solves this issue by welding the aggressive-fluid channel while keeping the secondary side gasketed.

Benefits:

- Reduced leakage risk

- Improved pressure handling

- Lower gasket exposure

- Controlled maintenance access

- Better long-term reliability

Industries such as cold storage, refrigeration plants, and chemical manufacturing widely use semi welded configurations.

Engineering Design of a Welded Plate

Every welded plate must be manufactured with precision. Key design parameters include:

- Plate thickness (commonly 0.6–1.0 mm or higher)

- Corrugation angle

- Port diameter

- Material grade (SS316, Titanium, special alloys)

- Laser welding quality

- Pressure rating

Proper welding technique ensures:

- Uniform heat distribution

- No micro-cracks

- Structural rigidity

- Pressure containment

According to industrial heat transfer studies referenced by institutions such as MIT OpenCourseWare (https://ocw.mit.edu), turbulence enhancement significantly improves thermal efficiency — which is why plate corrugation patterns matter greatly.

Applications of Welded Plate and Frame Heat Exchanger

A welded plate and frame heat exchanger is widely used in:

- Petrochemical plants

- Oil and gas processing

- Ammonia refrigeration

- Chemical manufacturing

- Power plants

- Marine cooling

- Heat recovery systems

These industries require consistent thermal control under fluctuating load conditions.

For complete industrial solutions, visit SRJ Heatt Exchangers India Pvt. Ltd. and learn more about expertise at About Us.

Comparison: Welded vs Gasketed Plate Heat Exchanger

| Feature | Welded Plate Heat Exchanger | Gasketed System |

| Pressure Handling | Very High | Moderate |

| Temperature Range | High | Medium |

| Maintenance | Moderate | Easy |

| Leak Risk | Very Low | Depends on gasket |

| Chemical Resistance | Excellent | Limited by gasket |

If process safety is critical, a welded heat exchanger is often preferred.

Key Advantages of Welded Plate Heat Exchanger

- Compact footprint

- High thermal efficiency

- Reduced leakage probability

- Suitable for aggressive fluids

- Lower long-term maintenance

- High-pressure stability

- Extended operational lifespan

These advantages make welded systems ideal for mission-critical operations.

Selection Checklist for Industrial Buyers

Before choosing a welded plate heat exchanger, evaluate:

- Operating pressure

- Fluid chemical composition

- Maximum temperature

- Flow rate

- Future expansion needs

- Cleaning accessibility

- Maintenance strategy

Providing accurate technical parameters ensures correct sizing and performance optimization.

Maintenance and Replacement Considerations

Although welded systems are durable, periodic inspection remains important.

Monitor for:

- Pressure imbalance

- Reduced heat transfer efficiency

- Fouling or scaling

- Structural vibration

Replacement components and support services are available at Replacement Parts for compatible industrial systems.

Frequently Asked Questions

1. What is a welded plate heat exchanger used for?

It is used in high-pressure and high-temperature industrial applications where gasket-only systems may not be suitable.

2. What is the difference between welded plate and semi welded plate heat exchanger?

In semi welded systems, plates are welded in pairs and partially gasketed, whereas fully welded systems eliminate gaskets between plates.

3. Are welded plate heat exchangers suitable for ammonia?

Yes, semi welded configurations are commonly used in ammonia refrigeration plants.

4. Can a welded plate and frame heat exchanger be expanded?

Some frame-supported welded systems allow limited expansion, depending on design.

5. Is maintenance difficult in welded heat exchangers?

Maintenance is less frequent compared to gasketed systems, but inspection requires professional handling.

Final Thoughts

A welded plate heat exchanger offers a strong balance between compact design and heavy-duty performance. Whether selecting a welded plate and frame heat exchanger for refinery duty or a semi welded plate heat exchanger for refrigeration plants, choosing the correct configuration ensures operational safety and long-term efficiency.

In industries where downtime and leakage risks cannot be tolerated, investing in a properly engineered welded heat exchanger is not just a technical decision — it is a strategic one.