SWEP Heat Exchanger Replacement Plates, Gaskets & Parts

SRJ Heat Exchangers India Pvt. Ltd. manufactures and supplies Tranter replacement heat exchanger plates, gaskets & parts for plate heat exchanger and plate and frame heat exchanger systems used in demanding industrial heating and cooling applications. These replacement components are engineered to align with original Tranter specifications, allowing existing systems to maintain thermal efficiency, sealing reliability, and long service life without any modification to the original equipment.

All Tranter replacement plates and gaskets are manufactured under controlled production processes using carefully selected materials. This ensures dimensional accuracy, consistent quality, and dependable performance in plate type heat exchanger applications operating under continuous duty.

Built for SWEP & Tranter Plate Heat Exchanger Operating Conditions

Tranter replacement plates and gaskets supplied by SRJ are designed to perform reliably in environments where plate heat exchangers operate under fluctuating temperatures, pressures, and varying process media.

- Accurate dimensional compatibility with Tranter plate heat exchanger units

- Stable thermal performance under changing operating conditions

- Reliable gasket sealing to minimize leakage and efficiency losses

- Suitable for long-term industrial, process, and HVAC plate heat exchanger use

Our focus is on maintaining uninterrupted system performance while reducing maintenance frequency and minimizing unplanned downtime.

Technical Summary – SWEP & Tranter Plate Heat Exchanger Components

SRJ supplies Tranter replacement plates, gaskets & associated parts in a wide range of industrial-grade material options selected to suit different plate heat exchanger operating requirements.

Plate Materials

High-quality stainless steel grades, titanium, nickel-based alloys, and corrosion-resistant materials suitable for plate heat exchanger duties.

Plate Thickness Range

Typically available between 0.4 mm and 1.0 mm, depending on the specific Tranter model and operating conditions.

Gasket Materials

Elastomer materials selected for temperature resistance, pressure tolerance, and chemical compatibility in gasketed plate heat exchanger systems.

Material selection is finalized after evaluating process media, operating temperature, and system pressure to ensure reliable service life and consistent performance.

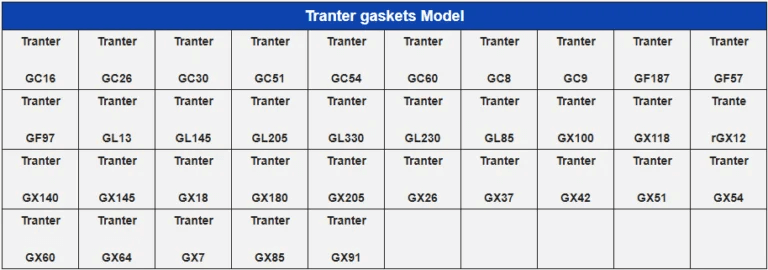

SWEP PHE & Tranter Plate Heat Exchanger Model Support

SRJ supports a wide range of SWEP PHE and Tranter plate and frame heat exchanger models used across industrial, process, and HVAC applications. Custom manufacturing is available based on samples or technical drawings, including older or discontinued Tranter models.

This capability allows existing plate heat exchanger systems to remain operational while maintaining compatibility, safety, and performance standards.

SWEP & Tranter Heat Exchanger Replacement – Technical Assistance

If you are evaluating replacement options for Tranter heat exchanger plates, gaskets, or related parts, our technical team can assist with compatibility verification, material selection, and application suitability.

By reviewing operating parameters such as temperature, pressure, and process media, we help identify the most appropriate Tranter replacement solution to support stable, efficient, and long-term system operation.

Frequently Asked Questions

Yes. SRJ manufactures OEM-fit replacement plates and gaskets compatible with SWEP heat exchangers and legacy Tranter plate heat exchanger models.

Yes. These products are specifically designed for replacement and refurbishment of existing Tranter plate heat exchanger systems.

They are suitable for industrial heating, cooling, HVAC, and process applications using plate and frame heat exchanger designs.

Yes. Gasket material selection is based on operating temperature, pressure range, and chemical compatibility requirements.

Identification is based on model details, operating conditions, or existing samples to ensure accurate selection and dependable system performance.

Our Clients

At SRJ Plate Heat Exchangers, we work closely with leading industrial brands, delivering reliable heat exchanger solutions backed by quality, performance, and long-term trust.