- About Us

- SRJ Heat Exchangers

- Replacement Parts

- APV PHE Gaskets & Plates

- Cetetherm PHE Gaskets & Plates

- Fischer PHE Gaskets & Plates

- Funke PHE Gaskets & Plates

- GEA (Kelvion) PHE Gaskets & Plates

- Polaris PHE Gaskets & Plates

- Reheat PHE Gaskets & Plates

- Schmidt Bretten PHE Gaskets & Plates

- Sondex PHE Gaskets & Plates

- SWEP PHE Gaskets & Plates

- Thermaline PHE Gaskets & Plates

- Tranter PHE Gaskets & Plates

- SRJAL PHE Gaskets & Plates

- Resources

-

SRJ PHE Gaskets & Plates Manufacturer

We provides PHE plates and gaskets, engineered for superior performance, durability, and hygiene in pasteurizing, cooling, and heating applications.

17+

Years Experience

99.9%

Error-Free Products

700+

Companies Served

Build Trust with Our Hard Work

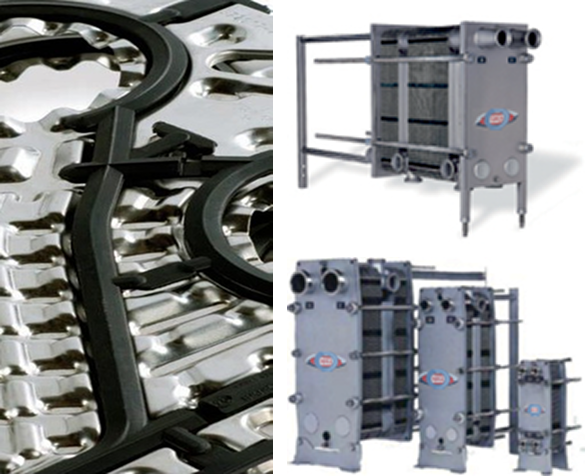

Plate Heat Exchangers

Our Plate Heat Exchanger range is specially designed for pasteurizing and general cooling/heating of beverages, dairy, brewery, chemical, textile, oil and gas as well as utilities. No mattress which product you select, you will acquire a proven, reliable, compact and hygienic design that will carry out its tasks effectively for many years to come.

What Are Heat Exchangers?

They are devices specifically designed for the efficient transfer of heat from one fluid to another fluid over a solid surface. This transfer of heat can either take the form of absorption or dissipation of heat. Heat exchangers can be found in everyday equipment from boilers, furnaces, refrigerators to air conditioning system.

How Can Heat Exchangers Be Put to Use for You?

As a heat transfer device, it is the function of a heat exchanger to transfer heat as efficiently as possible. this makes, it the ultimate device of choice for instance, when it come to saving energy by recovering wasted heat and making it useful again. When there is a waste of energy or a heat stream that is not recovered, a heat exchanger an covert that heat stream into something that we can use.

Semi Welded Heat Exchangers

Semi welded gasketed plate heat exchangers are used when gaskets are not suitable as one of the process media. Semi-welded GPHEs can also take a higher design pressure compared to fully gasketed plate-and-frame heat exchangers.

In the Semi-welded heat exchanger the refrigerant flows in laser-welded, sealed plate channels, and in the opposite channel the liquid brine flows in gasketed channels.

Applications

Semi-welded GPHEs are used in Sulphuric acid & refrigeration applications

1. H2SO4 Coolers

2. Evaporators

3. Condensers

4. Desuperheaters

5. Economizers/subcoolers

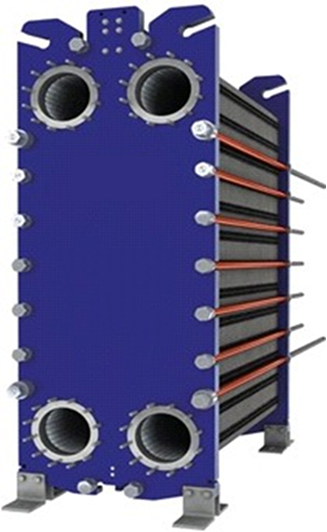

Brazed Plate Heat Exchangers

A plate type heat exchanger is a type of heat exchanger that uses metal plates to transfer heat between two fluids. This has a major advantage over a conventional heat exchanger in that the fluids are exposed to a much larger surface area because the fluids spread out over the plates. This facilitates the transfer of heat, and greatly increases the speed of the temperature change.

The plate heat exchangers we developed have high efficiency of heat exchange, superior to domestic congener products in technology. Under the same heat transfer coefficient, the resistance losses of the product can be controlled within 1/3 scope as tubular heat exchanger. The ripple type plate aims at deep membrane heat conduction coefficient, and forms a special channel.

Thus, liquid can bring the strong turbulence in the so low flow speed, and the rotational flow arises in the plate surface in order to shorten the time that the liquid rests on the surface, and avoid the dirty with self-purification. The quality of the product is reliable according to the request of the ISO9000 in design, purchase, production and inspection.

Welded Heat Exchangers

A full welded plate heat exchanger, it means that the heat-transfer plates are welded together with no need for an external gasket. Gasketed plate heat exchangers are suitable for many applications, but are limited in terms of temperature and pressure, coupled with the fact that there is always a risk of gasket failures and/or permeation. The same risks apply for semi-welded plate heat exchangers.

Spiral Heat Exchangers

Exceptionally well-suited for sludges, slurries, waste water, fouling, liquids with high viscosity, and liquids that contain fibers and solids, spiral heat exchangers are the definitive solution for applications that require treatment of challenging fluids. The design allows for a countercurrent flow that makes it possible to achieve very close temperature approaches.

Since we use coiled metal sheets instead of tube bundles, we can achieve very high thermal performance without sacrificing the channel gap that lets the media flow unimpeded.

The spiral coil itself also contributes to the turbulent flow, and the single-channel design helps alleviate fouling with a "self-cleaning" effect. Accumulated deposits create local increases in velocity, creating a scrubbing effect that is enough to loosen the build-up in fouling in most cases. Spiral heat exchangers to operate in very long sessions without maintenance or cleaning.

Some media, however, are so challenging that the heat exchanger requires more frequent maintenance and cleaning. With this in mind, we have designed hinged covers that are sealed with C-clamps, creating a swing door that is very easy to open and close without any special tools required, letting you access the entire coil for inspection and cleaning.

Wide Gap Plate Heat Exchangers

Wide Gap gasketed plate heat exchangers are designed for fibrous fluids and for fluids containing coarse particles. The wide gaps between plates allow fibers and particles to easily pass through the heat exchanger with minimum clogging.

They can be configured with wide-wide or wide-narrow channels, which make the units ideal for heating, cooling and interchanging duties. The smooth port design ensures fibers don't get stuck at the entrance.

Applications

1. Sugar

2. Distillery

3. Bioethanol

4. Pulp and paper

5. Petrochemicals

6. Condensers for heat recovery

Get Started Today

Upgrade your heat exchange system with our top-quality PHE plates and gaskets. Fast delivery and expert support are just a call away!

How We Deliver Your PHE Solutions

We create high-quality PHE plates and gaskets with care, ensuring your systems operate efficiently and reliably.

01

Material Selection

We choose top-grade materials like stainless steel and titanium (corrosion-resistant, high formability) tailored to your needs.

04

Accurate Assembly

The plates are carefully placed and pressed together, limiting any thinning to 23% of their original thickness for better durability.

02

Design Work

Our advanced tools and carefully made dies create perfect patterns to help your heat exchanger work its best.

05

Quality Checks

Each plate is checked for flatness (within less then 3mm for every 1000mm) and we look for tiny cracks in 1% of the batches.

03

Pressing Expertise

We use calibrated press machines (pressure controlled within design specs) to shape plates from 0.4mm to 1.0mm, with a standard thickness of around 0.5-0.6mm.

06

Final Finishing

We remove rough edges, clean, and polish the plates to make them rust-resistant and ready for long-lasting use.

Industries

Where We Serve

Our PHE plates and gaskets deliver exceptional performance and reliability across diverse industries,

ensuring efficient and durable solutions for your heat exchange needs.

Food Industry

Food Safety

Our plates keep your food processing clean and efficient with strong, leak-proof designs. We use corrosion-resistant Titanium and precise 0.4-1.0mm thickness to prevent leaks, ensuring safe food. This saves you cleaning time and keeps your products fresh.

Automotive

Vehicle Power

We provide durable plates for your car and truck cooling systems. Made with stainless steel and tight ±0.05mm thickness control, they handle high heat, boosting engine life and reducing your repair costs.

Industrial Refinery

Heavy Duty

Our solutions tackle challenging refinery tasks with precision and heat control. By using HC276 alloys and optimized corrugation, we ensure steady performance under pressure, reducing downtime for you.

Steel & Liquid Plant

Strong Support

We deliver reliable plates for steel and liquid handling with ease. Our 0.4-1.0mm thick plates and durable EPDM gaskets handle heavy loads, improving efficiency and lowering your replacement needs.

All Other Industries

Marine, HVAC, Dairy, Bioenergy, Energy, Liquor, Pharmacy — We Cover It All!

From ships to medicine, our PHE solutions fit every industry you need. With custom materials like Nickel for marine and VITON gaskets for pharmacy, we boost performance and reduce energy use across all sectors.

Petrochemical Plant

Safe Processing

Our plates ensure safe handling of chemicals with strong Titanium builds. The tight ±0.05mm thickness prevents leaks, keeping your plant secure and saving you repair time.

Chemical Industry

Reliable Performance

We offer tough plates and gaskets for chemical work. Using HC276 and leak-proof designs, they handle heat and pressure, reducing breakdowns and costs for you.

Easy Setup Guide

How to Install Your Plates

Installing your plate heat exchanger (PHE) plates is simple with our step-by-step guide. We make sure it’s easy for you to set up and keep your system running well for years.

01 Setting the Base

Gaskets and plates are used to separate the flowing mediums and prevent them mixing; gaskets are adhered to one side of each plate only. The plates hang upon a carry bar and are pressed together using clamping bolts. When the plates are compressed together, they are referred to as a ‘plate stack’. A guide bar ensures the plates are aligned correctly when the plate stack is opened and closed.

02 Joining the Pipes

The hot medium enters the heat exchanger through the hot medium inlet. Gaskets direct the hot medium as it flows through the heat exchanger. Each plate has an alternating gasket pattern. The hot medium flows into the space between a pair of plates, but does not flow into the space between the next pair of plates because the gaskets prevent this. The process continues so that each second set of plates is filled with the hot flowing medium.

Our Clients

Trusted Partners

Join a network of trusted partners who rely on our quality solutions. Our client logos represent our commitment to excellence and strong collaboration.

TESTIMONIAL

What Our Customers Say

Our customers inspire us every day! Here’s what they’re saying

about their experience and the difference our products make!

Quick Answers

FAQs

Got questions about our PHE plates and gaskets? We’ve got simple answers to help you. If you don’t find what you need, just call us to ask your query!

Superior performance, durability, and hygiene for efficient pasteurizing, cooling, and heating.

Pasteurizing, cooling, and heating applications with reliable performance.

High-quality materials and hygienic design ensure performance and reliability.

Yes, their compact, hygienic design simplifies cleaning and maintenance.

Let’s Connect

Transform Your Production Process in Minutes! Efficient Heat Exchange Solutions for Immediate Impact in Any Industry.

PHE PLATES | GASKETS | CUSTOM SOLUTIONS

Get personalized PHE plate and gasket solutions tailored to your needs. Our team is ready to assist you!