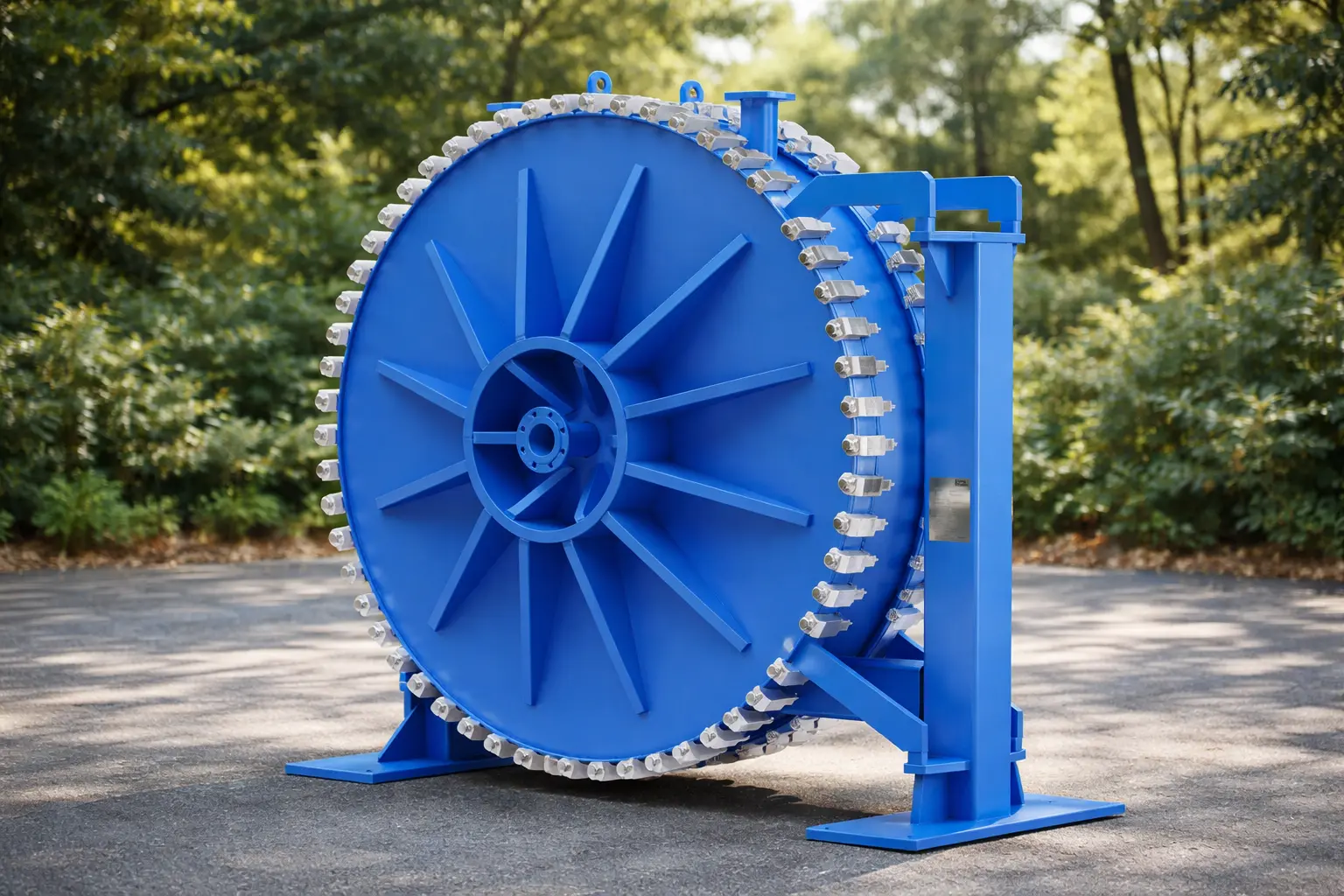

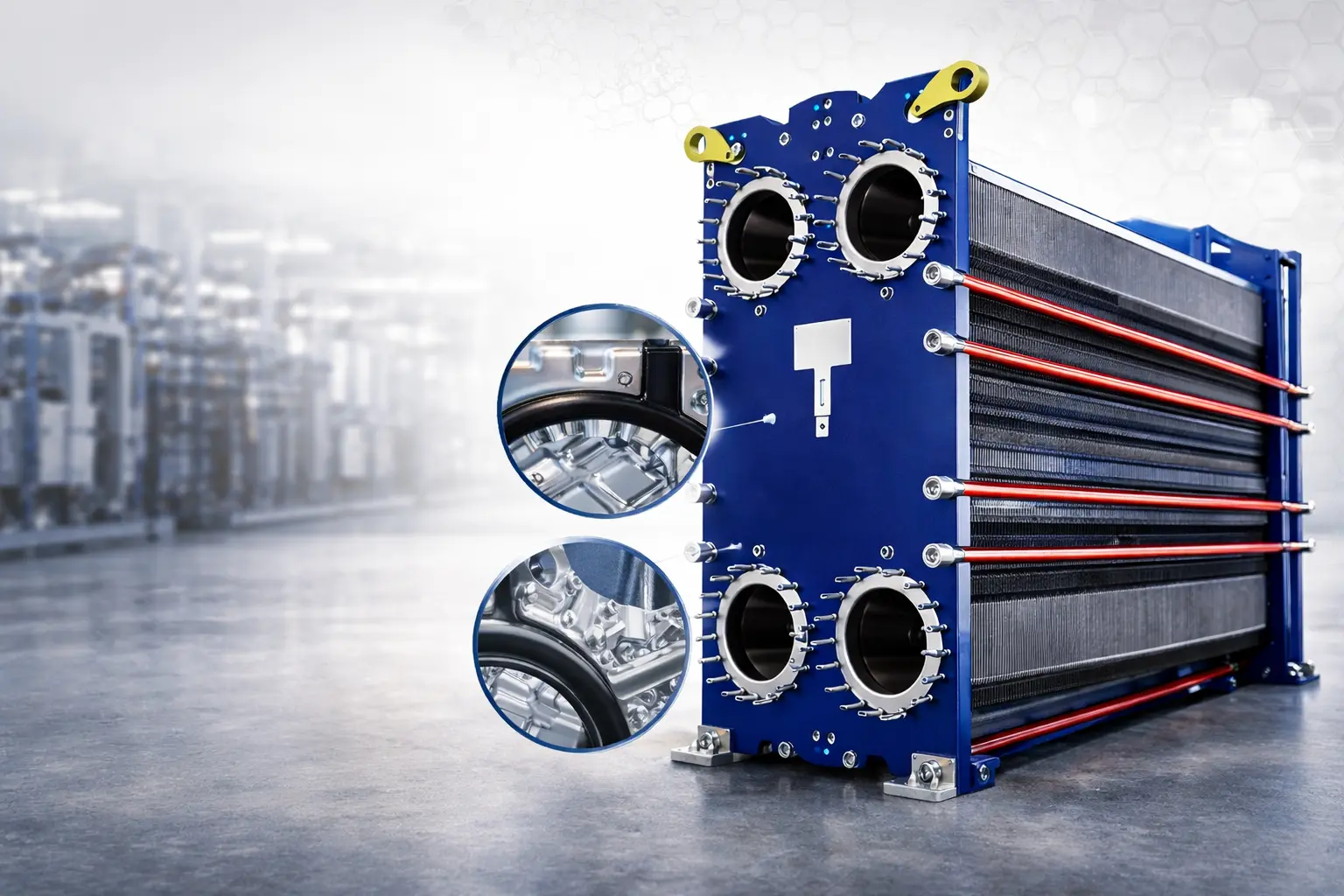

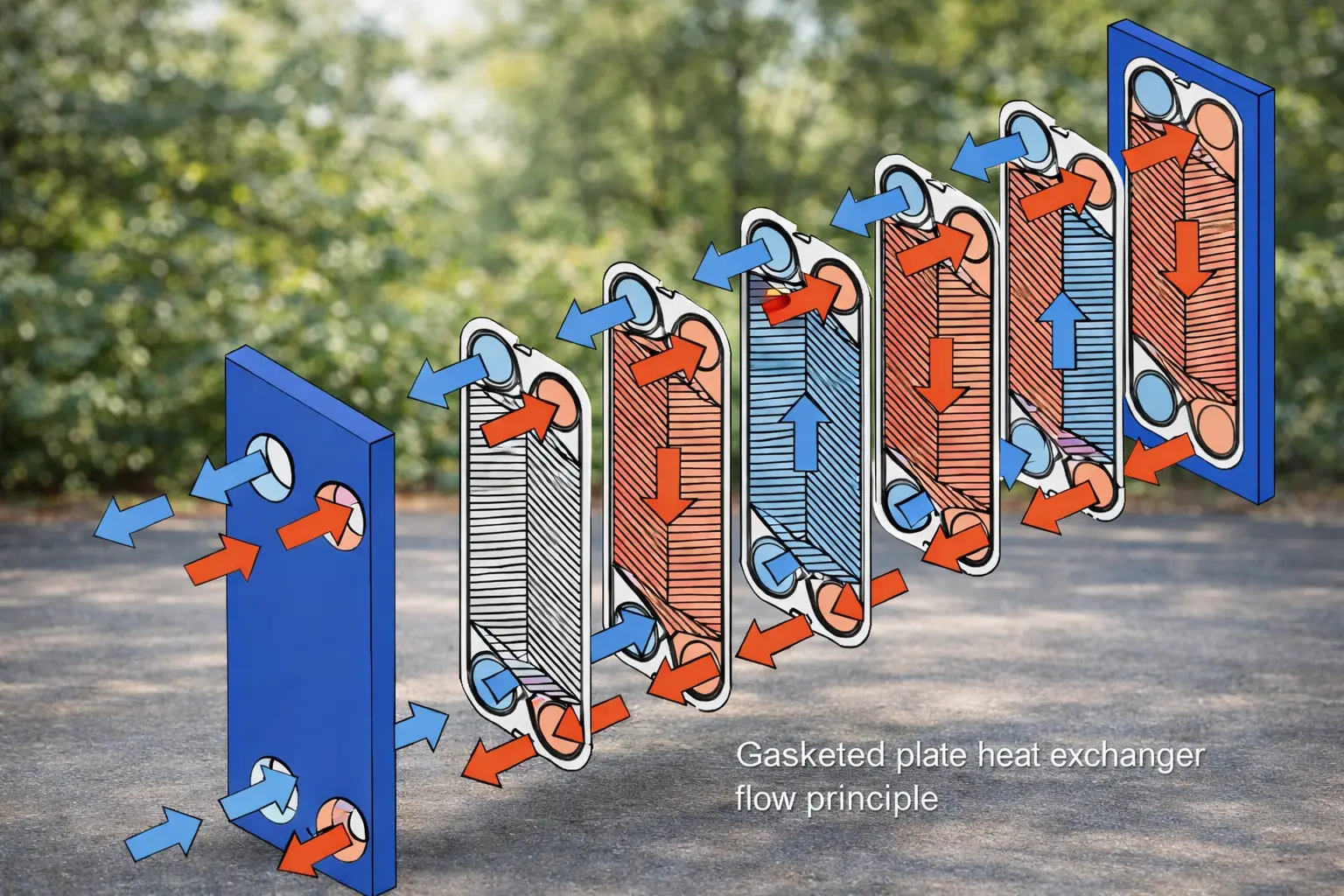

Gasketed Plate Heat Exchangers

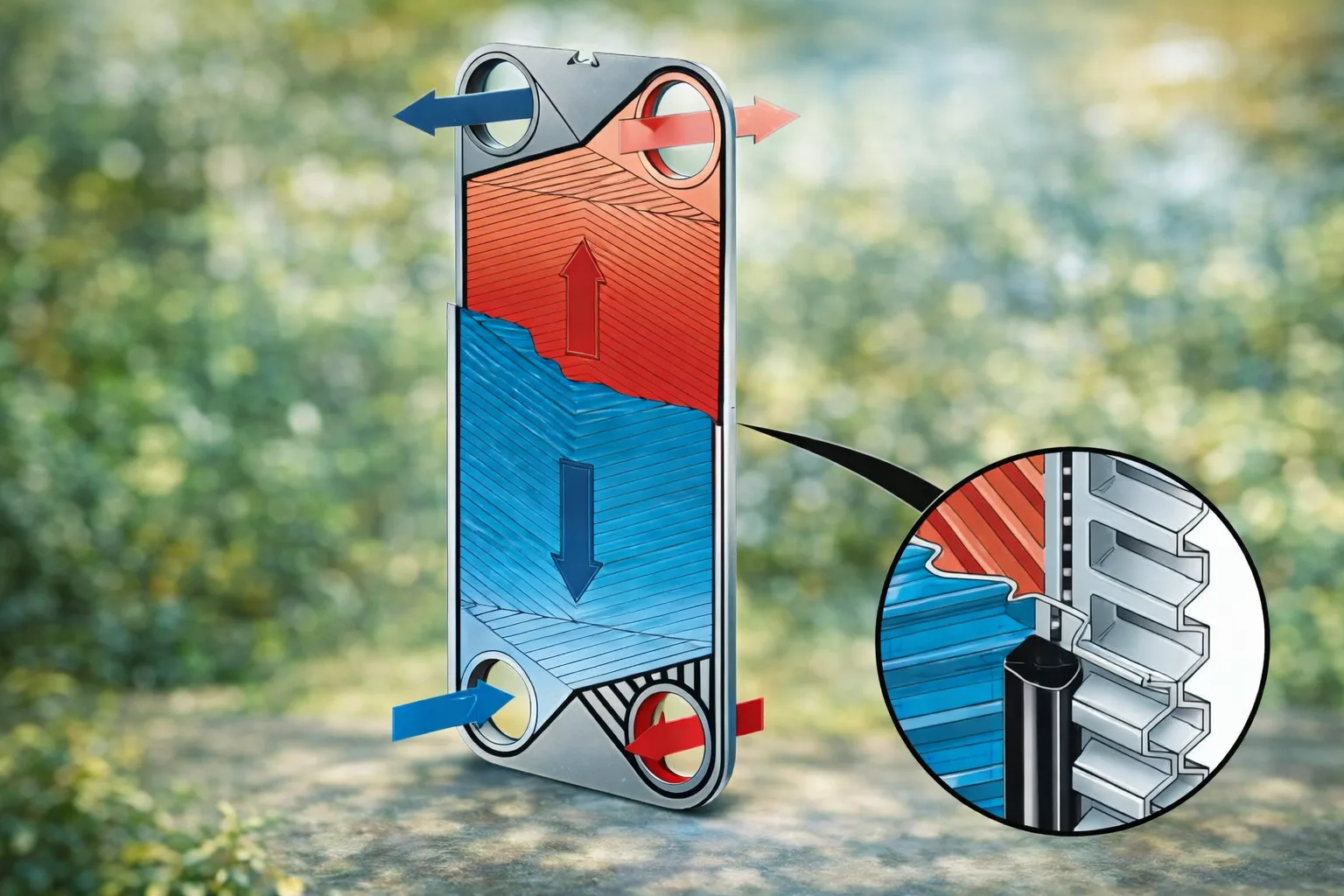

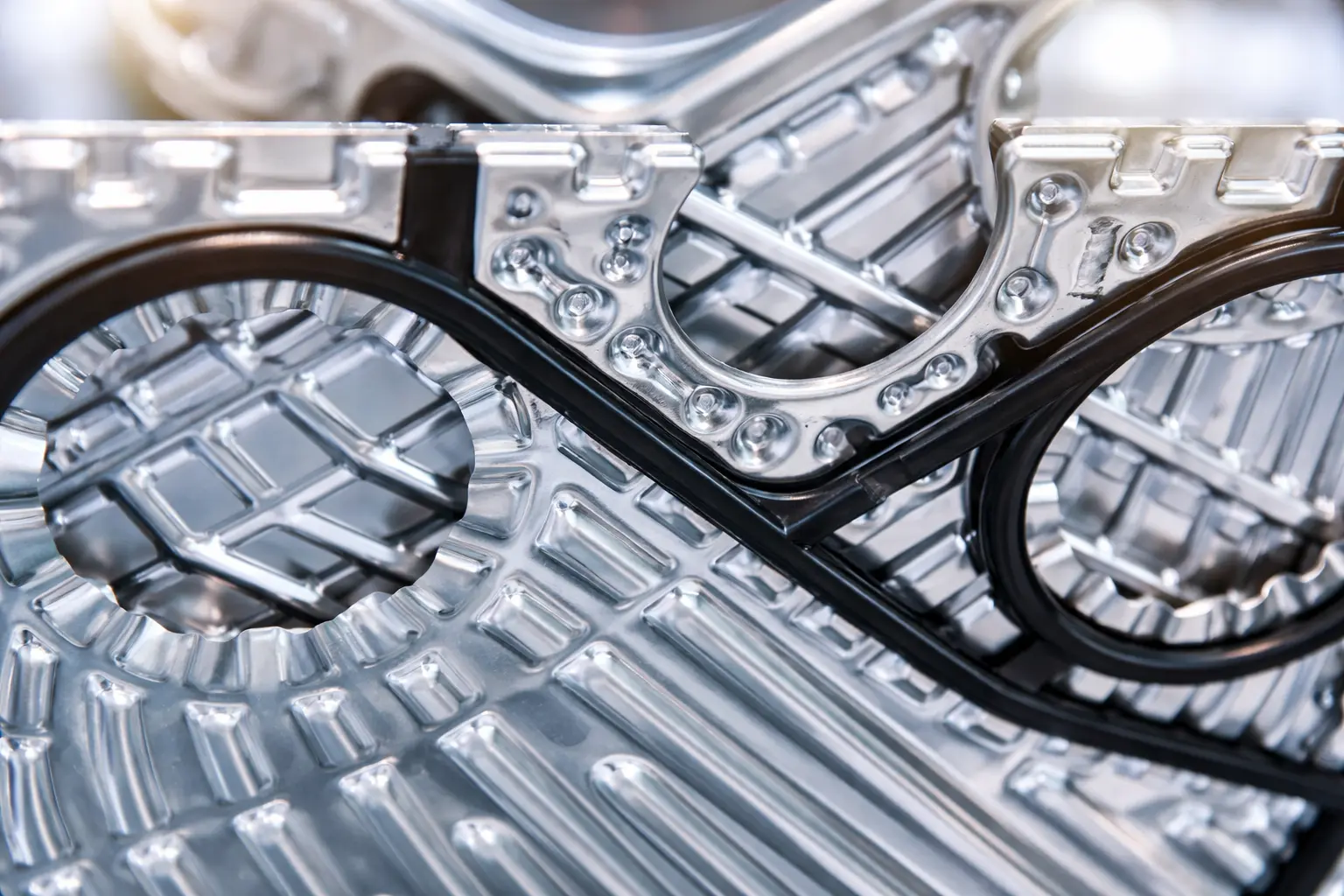

In a plate type heat exchanger, hot and cold fluids flow through alternate channels formed by plates. The corrugated surface creates turbulence, improving heat transfer efficiency even at low temperature differences. Gaskets seal each plate, ensuring safe operation without fluid mixing.