In the world of thermal management and industrial processing, efficiency is the currency of success. Whether you are managing a massive chemical plant, a hygienic food processing line, or a complex HVAC system, the equipment you choose defines your operational costs. Enter the plate and frame heat exchanger—a marvel of engineering designed to maximize heat transfer while minimizing footprint.

If you are looking for a plate type heat exchanger or simply trying to understand the nuances of a phe heat exchanger, this comprehensive guide is for you. We will dive deep into the mechanics, maintenance, and selection criteria for these critical components, ensuring you have the expert knowledge needed to optimize your systems.

What is a Plate Heat Exchanger?

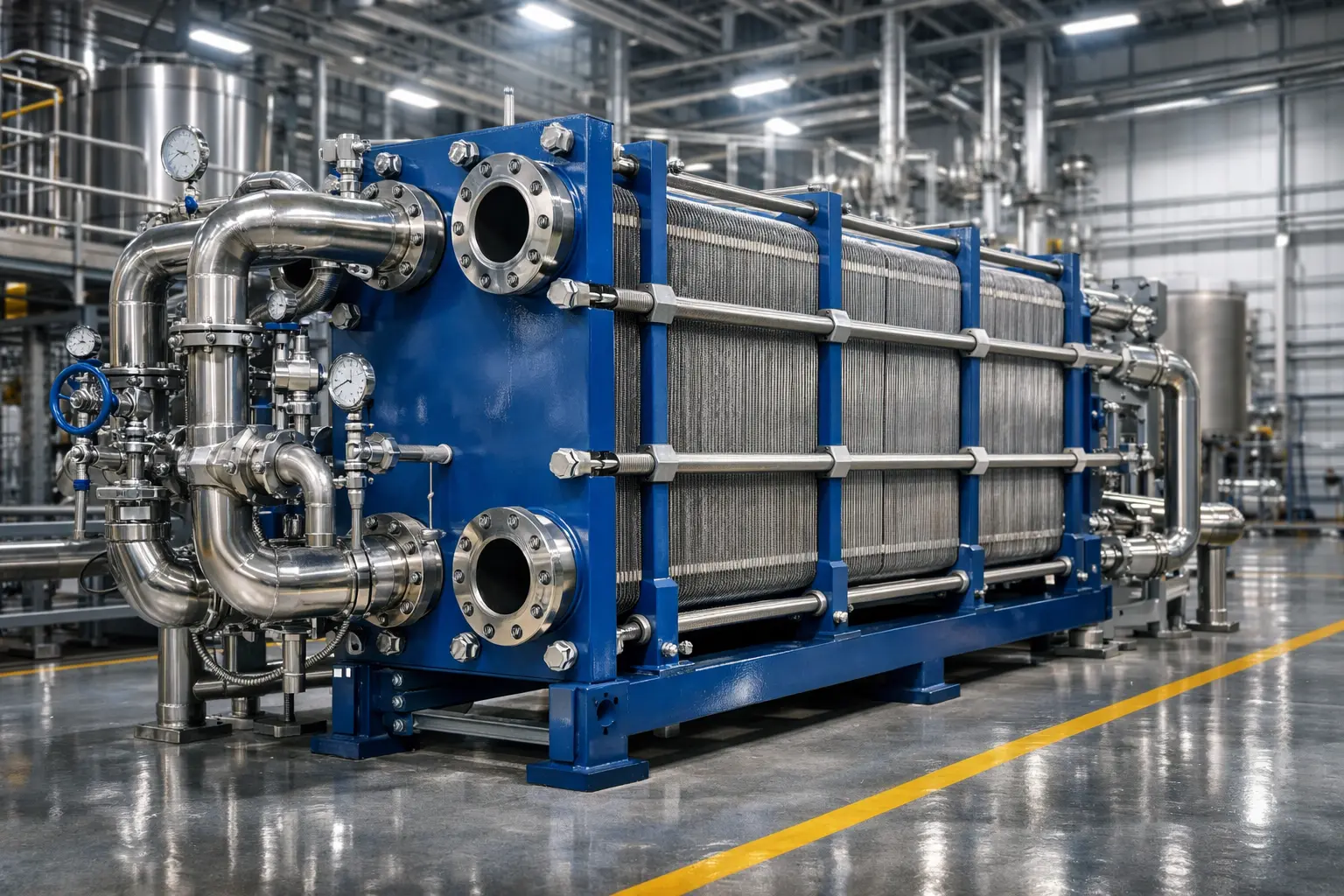

At its core, a plate heat exchanger (PHE) is a device designed to transfer thermal energy between two fluids without them mixing. Unlike traditional shell-and-tube designs, a plate exchanger utilizes a series of corrugated metal plates to create heat transfer channels.

The concept is a brilliant example of a plate to plate heat exchanger mechanism. Fluids flow in alternating channels, separated by thin metal plates. This design creates a massive surface area in a compact frame, allowing for extremely efficient heat exchange. The corrugations on every phe plate are not just for structural integrity; they induce turbulence in the fluid, which significantly enhances the heat transfer coefficient and reduces fouling (the buildup of unwanted material).

Why Choose a Plate and Heat Exchanger System?

When engineers compare a plate and heat exchanger setup to other technologies, several distinct advantages emerge:

- High Efficiency: The counter-current flow and high turbulence allow for close temperature approaches (as low as 1°C).

- Compact Design: A plate heat exchanger requires only 20-30% of the floor space of a shell-and-tube exchanger of the same capacity.

- Flexibility: Particularly with a plate and frame heat exchanger, you can easily expand capacity by loosening the frame and adding more plates.

- Easy Maintenance: The units can be dismantled for cleaning and inspection, making it easy to replace a single plate for heat exchanger maintenance rather than the whole unit.

Types of Plate Heat Exchangers

Understanding the specific type of plate heat exchangers required for your application is crucial for longevity and performance.

1. Gasketed Plate Heat Exchangers

This is the most common industrial variant. It consists of a pack of plates with gaskets sealing the channels and directing the fluids into alternate passages. The entire pack is compressed between a fixed frame plate and a movable pressure plate.

- Best for: HVAC, general industrial cooling, and food processing where frequent cleaning is required.

- Benefit: Fully dismantlable for easy maintenance.

- Learn More: Explore Gasketed Plate Heat Exchangers for detailed specifications.

2. Brazed Plate Heat Exchangers

In these units, the plates are brazed together (usually with copper or nickel) in a vacuum furnace, eliminating the need for gaskets and heavy frames.

- Best for: High-pressure and high-temperature applications, refrigeration, and district heating.

- Benefit: extremely compact and leak-proof.

- Learn More: Check out high-performance Brazed Plate Heat Exchangers.

3. Welded and Semi-Welded PHEs

For aggressive fluids that might destroy standard gaskets, welded options are ideal. A semi-welded phe heat exchanger uses laser welds to seal the channel for the aggressive fluid, while the non-aggressive side remains gasketed for serviceability.

- Best for: Refrigeration (ammonia), chemical processing, and corrosive fluids.

- Learn More: See options for Semi-Welded Plate Heat Exchangers.

The Anatomy of Efficiency: Plates and Gaskets

The soul of any phe heat exchanger lies in its components. The selection of the right plate for heat exchanger duty is a matter of material science and fluid dynamics.

The Plates

The heat exchanger plate is usually pressed from a single sheet of metal. Common materials include:

- Stainless Steel (304/316): For water, mild acids, and food products.

- Titanium: Essential for seawater and chloride-rich fluids to prevent corrosion.

- Hastelloy/Inconel: For highly aggressive acids and corrosive environments.

The corrugation pattern (chevron angle) on the phe plate dictates the pressure drop and thermal efficiency. High-theta plates offer high heat transfer but higher pressure drop, while low-theta plates offer the reverse.

The Gaskets

Gaskets are the sealing heroes of a plate and frame heat exchanger. They must withstand the temperature and chemical nature of the process fluids.

- NBR (Nitrile): Ideal for oil and water applications up to 138°C.

- EPDM: Perfect for steam, water, and weak acids up to 160°C.

- Viton (FKM): Required for organic solvents and high temperatures.

When your system efficiency drops, it is often time to look at Replacement Parts. Using high-quality Heat Exchanger Plates and gaskets is vital to return the unit to OEM specifications.

Technical Comparison: Plate vs. Shell & Tube

To provide a clear “EEAT” (Expertise, Authoritativeness, Trustworthiness) perspective, let’s look at the data. According to research from standard engineering practices, the difference in heat transfer coefficients is stark.

| Feature | Plate Heat Exchanger | Shell & Tube Exchanger |

| Heat Transfer Coefficient (K-value) | 3500 – 7500 W/m²K | 1200 – 2000 W/m²K |

| Space Requirement | Low (Compact) | High (Requires bundle pulling space) |

| Approach Temperature | As low as 1°C | Typically 5°C – 10°C |

| Fouling Factor | Low (High turbulence) | Moderate to High |

| Expandability | Easy (Add plates) | Impossible (Fixed shell) |

Source Reference: For a deeper dive into heat transfer coefficients, refer to resources like The Engineering Toolbox or standard Thermodynamics texts.

Industries Driving the Demand for Plate Exchangers

The versatility of the plate type heat exchanger makes it ubiquitous across various sectors.

1. HVAC and Refrigeration

In modern green buildings, a plate to plate heat exchanger acts as a “pressure breaker” between high-rise static heads and cooling towers. They are also integral to district cooling networks.

2. Food and Beverage

Pasteurization requires precise temperature control. A plate and heat exchanger system can heat milk to pasteurization temperature and regenerate heat from the cooling cycle, saving massive amounts of energy.

3. Chemical Processing

Handling aggressive acids requires robust engineering. Companies often rely on SRJ Heat Exchangers for expert consultation on material compatibility, ensuring the plate exchanger does not fail under chemical attack.

4. Marine and Power

Cooling massive engines and turbines requires the high-capacity throughput of a phe heat exchanger. Titanium plates are standard here to resist the corrosive effects of seawater cooling.

Maintenance: The Key to Longevity

Even the best plate and frame heat exchanger requires maintenance. Over time, calcium deposits, biological growth, or process debris can foul the plates.

Cleaning In Place (CIP):

For light fouling, circulating a cleaning solution through the plate exchanger without opening it is effective. This dissolves scale and returns efficiency.

Manual Cleaning:

For heavy fouling, the unit must be opened. This involves:

- Loosening the carrying bars.

- Separating the phe plate pack.

- Pressure washing each plate.

- Inspecting gaskets for cracks or deformation.

If you find damaged components, sourcing reliable replacements is critical. Whether you need SRJ/AL Replacement Plates & Gaskets or components for other brands like Tranter/Swep, ensuring fitment accuracy is non-negotiable.

Pro Tip: Always tighten the plate pack to the specific dimension (A-dimension) specified in your manual. Over-tightening can crush the plates; under-tightening will cause leaks.

Selecting the Right Manufacturer

Choosing a plate for heat exchanger manufacturing partner is as important as the hardware itself. You need a team that understands thermodynamics, not just sales.

At SRJ Heat Exchangers, we pride ourselves on being industry leaders. As highlighted in our About Us section, our expertise spans across manufacturing new units and providing spares for almost every major global brand.

We ensure that every plate type heat exchanger leaving our facility meets rigorous quality standards. Whether you need a specialized Spiral Heat Exchanger for sludge applications or a standard gasketed unit for water cooling, our engineering team provides tailored solutions.

Frequently Asked Questions (FAQ)

1. How often should I service my plate heat exchanger?

Maintenance intervals depend on the fluid types. For clean water, a plate heat exchanger might run for years without opening. For process fluids or hard water, annual inspection is recommended. If you notice an increase in pressure drop or a decrease in temperature difference, it is time to check for fouling.

2. Can I increase the capacity of my existing PHE?

Yes, this is a primary benefit of a plate and frame heat exchanger. Provided the frame has enough remaining length on the carrying bar, you can add more pairs of plates to increase the heat transfer area and capacity.

3. What is the difference between a gasketed and a brazed plate exchanger?

A gasketed plate heat exchanger uses rubber seals and can be opened for cleaning or expansion. A brazed plate heat exchanger is permanently sealed (brazed) and cannot be opened. Brazed units are more compact and handle higher pressures but are disposable if they foul heavily or leak.

4. How do I choose the right plate material?

The material depends on the fluid’s chloride content and acidity.

- SS304: General water/oil.

- SS316: Standard for most industrial applications/food.

- Titanium: Required for saltwater or high-chloride fluids.

- Hastelloy/Titanium Palladium: For aggressive acids.

Consulting with experts at SRJ Heat Exchangers can help prevent costly corrosion failures.

5. Why is my plate heat exchanger leaking?

Leaks usually occur due to three reasons:

- Old Gaskets: Rubber loses elasticity over time (compression set).

- Improper Tightening: The plate pack is not tightened to the correct dimension.

- Pressure Spikes: Sudden pumps starting (water hammer) can blow out gaskets.

If you have a leak, check the tightening dimension first, then inspect gaskets for replacement.

Conclusion

The plate heat exchanger remains one of the most efficient thermal transfer technologies available today. From the simple phe plate design to complex multi-pass plate and heat exchanger configurations, these units save energy, reduce carbon footprints, and optimize industrial processes globally.

Whether you are designing a new plant or maintaining an existing system, understanding the nuances of your plate type heat exchanger is vital. Prioritize quality components, regular maintenance, and expert consultation.

For all your heat transfer needs, from complete units to specific Heat Exchanger Plates, trust the expertise of SRJ Heat Exchangers to keep your operations running cool and efficient.