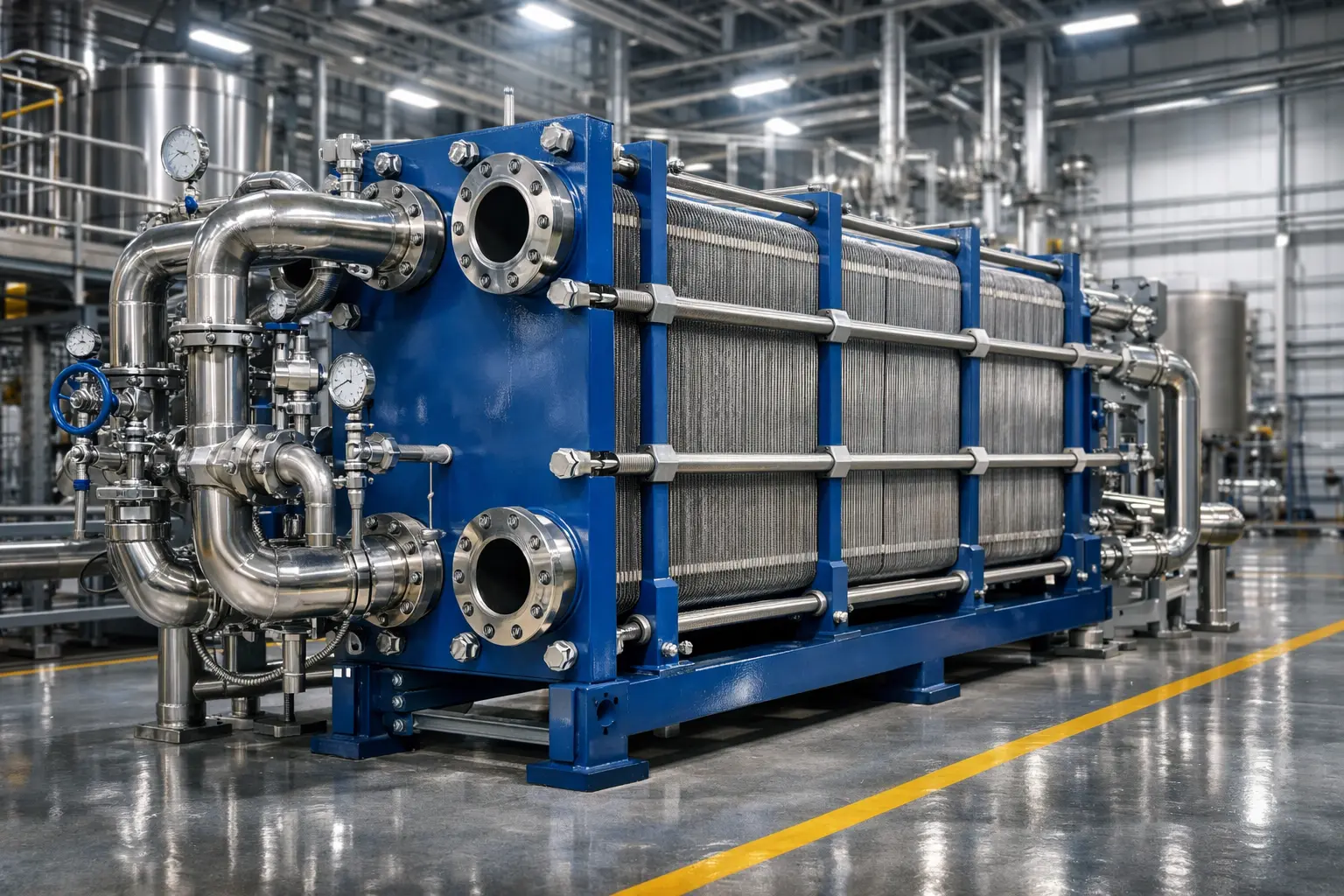

Understanding the plate heat exchanger price is essential for industries planning new installations, system upgrades, or replacement projects. Whether you are evaluating a compact unit for HVAC or a heavy-duty spiral plate heat exchanger for chemical processing, pricing depends on multiple technical and operational factors — not just size alone.

In this guide, we break down what influences plate heat exchanger price, compare different configurations, explain where a spiral plate heat exchanger is most suitable, and help industrial buyers make informed decisions based on performance, durability, and lifecycle value.

What Determines Plate Heat Exchanger Price?

The plate heat exchanger price varies significantly depending on:

- Type of exchanger (gasketed, welded, brazed, spiral)

- Plate material (SS304, SS316, titanium, nickel alloys)

- Plate thickness and design pattern

- Pressure and temperature rating

- Number of plates (heat transfer area)

- Gasket material

- Frame construction quality

- Industry compliance standards

Price should always be evaluated against total lifecycle cost — including maintenance, energy efficiency, and operational reliability.

According to energy efficiency data published by the U.S. Department of Energy, optimized heat exchanger selection can significantly reduce long-term energy consumption in industrial systems.

Approximate Plate Heat Exchanger Price Range (Industrial Use)

Below is a general industrial pricing overview. Actual pricing depends on specifications and project scope.

| Type | Application | Approximate Price Range (Indicative) |

| Gasketed Plate Heat Exchanger | HVAC / Dairy | Mid-range |

| Semi-Welded Plate Exchanger | Chemical | Higher |

| Fully Welded Plate Exchanger | High pressure systems | Premium |

| Brazed Plate Heat Exchanger | Refrigeration | Lower-mid |

| Spiral Plate Heat Exchanger | Slurry / viscous fluids | Application-based pricing |

For industrial-grade options and consultation, explore Gasketed Plate Heat Exchangers and Welded Plate Heat Exchangers.

Why Spiral Plate Heat Exchanger Is Used in Heavy-Duty Applications

A spiral plate heat exchanger differs from conventional plate and frame systems. It consists of two long metal plates wound into a spiral shape, forming continuous channels for fluid flow.

Key Advantages:

- Handles viscous fluids and slurry

- Reduced fouling due to single-channel flow

- Self-cleaning flow pattern

- High reliability in continuous industrial operation

- Lower maintenance frequency

Spiral configurations are ideal for:

- Petrochemical plants

- Effluent treatment

- Pulp and paper industries

- Distilleries

- Heavy chemical processing

Learn more about industrial spiral systems at Spiral Heat Exchangers.

Factors That Increase Plate Heat Exchanger Price

1. Material Upgrade

Titanium or special alloys increase cost but improve corrosion resistance.

2. Higher Pressure Rating

Heavy frame and thicker plates add to price.

3. Hygienic Design Requirements

Food and pharmaceutical industries require specialized surface finishing.

4. Custom Manufacturing

Customized port size, plate pattern, or expansion capability affects pricing.

5. Brand Compatibility

Replacement systems designed for specific industrial brands may influence cost.

For example, compatible solutions are available at:

- Replacement Parts

- APV SPX Replacement Plates & Gaskets

- GEA Kelvion Replacement Plates & Gaskets

- Funke & HRS Replacement Plates & Gaskets

Spiral Plate Heat Exchanger vs Plate and Frame: Cost Comparison

| Feature | Plate & Frame | Spiral Plate Heat Exchanger |

| Maintenance | Easy plate removal | Low fouling, less frequent cleaning |

| Footprint | Compact | Slightly larger |

| Initial Price | Moderate | Application-specific |

| Viscous Fluid Handling | Limited | Excellent |

| Pressure Capacity | High | High |

While spiral systems may have a higher upfront investment in some cases, they often reduce operational downtime in slurry or viscous applications.

Technical fundamentals of heat transfer mechanisms are widely documented by academic institutions such as MIT and research databases, emphasizing that flow dynamics strongly impact exchanger efficiency.

Lifecycle Cost vs Initial Plate Heat Exchanger Price

Many buyers focus only on upfront plate heat exchanger price, but true evaluation should include:

- Energy efficiency savings

- Maintenance frequency

- Replacement part availability

- Downtime impact

- Expected service life

A slightly higher initial investment in properly engineered systems can result in long-term operational savings.

For detailed product overview, visit SRJ Heatt Exchangers India Pvt. Ltd. and learn about the company’s expertise at About Us.

How to Get an Accurate Plate Heat Exchanger Price Quote

To receive a precise quotation, provide:

- Flow rate (m³/hr)

- Inlet & outlet temperatures

- Fluid type

- Operating pressure

- Required heat duty (kW)

- Available installation space

Without technical parameters, pricing can only be estimated broadly.

When Should You Choose a Spiral Plate Heat Exchanger?

Select a spiral configuration when:

- Fluids contain suspended solids

- Fouling tendency is high

- Continuous operation is critical

- Cleaning shutdown must be minimized

- Sludge or slurry handling is required

Spiral units are engineered for demanding industrial environments where conventional plate systems may clog faster.

Frequently Asked Questions (FAQ)

1. What is the average plate heat exchanger price in India?

The price depends on plate size, material, pressure rating, and type. Industrial systems are quoted based on technical specifications rather than fixed pricing.

2. Is spiral plate heat exchanger more expensive than plate and frame?

In some applications, spiral units may cost more initially but offer lower maintenance and better performance for viscous fluids.

3. Does material grade impact plate heat exchanger price?

Yes. Titanium and special alloys significantly increase cost compared to standard stainless steel.

4. Which industries use spiral plate heat exchangers?

Petrochemical, wastewater treatment, pulp & paper, and chemical industries frequently use spiral designs.

5. How can I reduce long-term operating cost?

Select the correct exchanger type, ensure proper installation, and use high-quality replacement parts when needed.

Final Thoughts

Choosing the right system is not just about comparing plate heat exchanger price. It requires technical evaluation, long-term performance planning, and application-based decision making.

For industries dealing with complex fluids, a spiral plate heat exchanger offers reliability and reduced fouling. For general heating and cooling duties, gasketed or welded plate systems remain highly efficient and cost-effective.

A well-engineered solution ensures consistent thermal performance, energy savings, and operational stability across industrial processes.