- About Us

- SRJ Heat Exchangers

- Replacement Parts

- APV PHE Gaskets & Plates

- Cetetherm PHE Gaskets & Plates

- Fischer PHE Gaskets & Plates

- Funke PHE Gaskets & Plates

- GEA (Kelvion) PHE Gaskets & Plates

- Polaris PHE Gaskets & Plates

- Reheat PHE Gaskets & Plates

- Schmidt Bretten PHE Gaskets & Plates

- Sondex PHE Gaskets & Plates

- SWEP PHE Gaskets & Plates

- Thermaline PHE Gaskets & Plates

- Tranter PHE Gaskets & Plates

- SRJAL PHE Gaskets & Plates

- Resources

-

Maintenance Tips to Extend the Life of Heat Exchanger Plates (Gasketed PHEs)

Category: Blogs

Procurement managers carry two parallel responsibilities: buy reliable plate heat exchangers (PHEs) and make those assets pay back for years. The second responsibility—lifetime performance—is largely a maintenance question.

The good news: with a disciplined, checklist-driven program, gasketed PHEs deliver stable thermal performance, fewer leaks, and longer intervals between overhauls.

Below is a practical, engineering-grade guide you can give to maintenance teams, plant managers, and service partners to reduce fouling, stop nuisance leaks, and slow gasket wear—without bloating downtime or chemical costs.

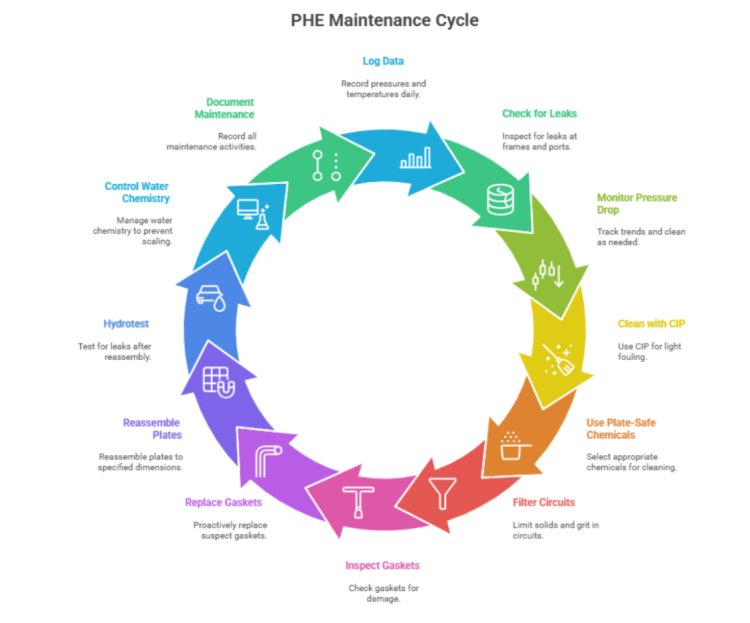

The 12-Point PHE Maintenance Checklist

-

Log pressures & temperatures daily and compare to baseline.

-

Walk-around leak check at frames, ports, and plate edges each shift.

-

Track pressure drop trends; clean when ΔP rises or when approach temperatures worsen.

-

CIP first for light/moderate fouling; open only if performance doesn’t recover.

-

Use plate-safe chemicals (e.g., citric/sulfamic for carbonate scale; alkaline for organics).

-

Filter your circuits (strainers/screens) to limit erosive solids and grit.

-

Inspect gaskets on every opening for cracks, flattening (compression set), and swelling.

-

Replace suspect gaskets proactively; keep OEM-spec spares on hand.

-

Reassemble to the specified plate-pack dimension, tightening diagonally and evenly.

-

Hydrotest after rebuild; heat up and pressurize gradually to avoid shocks.

-

Control water chemistry (hardness, chlorides) to reduce scaling and corrosion.

- Document everything—dates, ΔP, approach temps, plate-pack dimension, parts changed.

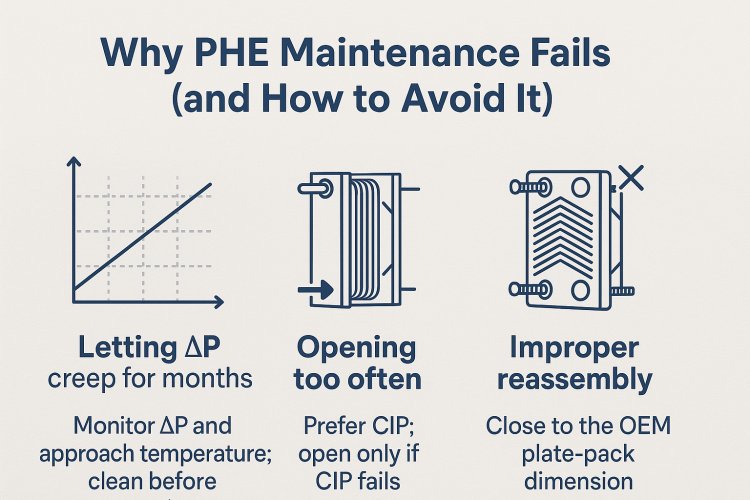

Why PHE Maintenance Fails (and How to Avoid It)

Three patterns drive most premature overhauls:

-

Letting ΔP creep for months. Fouling raises the pressure drop long before the output falls. A weekly chart of ΔP and approach temperature (hot-out minus cold-in) will tell you when to clean—before energy costs and quality problems spike.

-

Opening too often. Every open/close cycle stresses gaskets. Prefer CIP when possible; open only if CIP fails to restore performance.

-

Improper reassembly. Over-tightening crushes gaskets; under-tightening invites leaks. Always close to the OEM plate-pack dimension (“A”)—not guesswork torque.

Routine Inspection & Service Intervals

Daily / per shift

-

Visual walk-around: damp marks, salt crystals, or sticky residue at plate edges/ports.

-

Record inlet/outlet temperatures and ΔP across the PHE; flag deviations.

Monthly

-

Compare logs to baseline. If ΔP is trending up or the approach temperature worsens, plan a CIP.

-

Inspect frames, tie bolts, and guide bars; clean and lightly lube mechanicals so plates slide freely.

6–12 months

-

Scheduled service: CIP or open-and-clean, internal inspection, plate-pack measurement, selective gasket replacement. Heavier fouling duties may need twice-yearly cleaning; cleaner closed loops may run longer.

3–4 years (or by condition)

- Full strip, plate-by-plate inspection, dye-penetrant on suspect plates, complete regasketing if elastomers are aged.

Cleaning Strategy: Clean-In-Place (CIP) vs. Manual

When to use CIP

If the exchanger shows moderate ΔP increase or minor heat loss, CIP is faster, safer for gaskets, and minimizes downtime. Typical steps:

-

Isolate & drain both circuits.

-

Back-flush with water (reverse flow) until clear.

-

Circulate a cleaning solution warm enough for the chemistry to work, at a safe pressure.

-

Neutralize (if acid used) and rinse to neutral pH; return to service gradually.

Chemistry rule of thumb

-

Alkaline CIP (e.g., caustic blends) for fats/oils/biofilm.

-

Acid CIP (citric/sulfamic/phosphoric) for carbonate scale/rust—avoid chlorides on stainless.

-

Use OEM-vetted products or proven equivalents; follow concentration/temperature limits.

When to open and clean

Open if CIP fails, if you need plate inspection, or when deposits are heavy/stubborn. Best practices:

-

Number plates: keep orientation.

-

Remove clip-on gaskets; never use metal brushes on plates—use nylon/plastic and approved descalers.

-

Clean gasket grooves; remove old adhesive completely (chloride-free solvents only), rinse thoroughly, then dry and inspect for pinholes against light.

Gasket Care: The Fastest Way to Kill - or Save - Your PHE

What to look for

-

Compression set (flattened, shiny, hardened).

-

Cracks/cuts or chemical swelling.

-

Edges out of groove (assembly issue or gasket stretch). If in doubt, replace now rather than gambling on a restart.

Replacement do’s

-

Use OEM-specified elastomer (NBR, EPDM, FKM, etc.) matched to temperature and fluid.

-

Clean grooves meticulously; install without twist or stretch.

-

For glue-in styles, use chloride-free recommended adhesive; follow cure times.

-

Replace in sets on aged units; keep FIFO-tracked spares.

-

Store spares cool, dark, dry, sealed—away from UV and ozone sources (motors, welders).

Reassembly & Tightening (Where Most Leaks Begin)

-

Confirm plate sequence and orientation (L/R pattern), check for end-plate gasket variations.

-

Clean and lightly lube tie-bolt threads; never contaminate gaskets.

-

Tighten diagonally in small increments, keeping frame plates parallel and watching all four corners.

-

Close to the specified plate-pack dimension (“A”)—do not exceed minimum; do not guess torque.

-

Hydrotest with water; vent air; step up pressure gradually. After first heat-up, recheck for relaxation and retighten to spec if required.

Operating Practices that Extend Plate & Gasket Life

-

Avoid thermal/pressure shocks. Open valves slowly; use soft starts on pumps/steam.

-

Control solids. Add strainers/filters to keep grit from eroding inlets/corrugations.

-

Mind water chemistry. Treat hardness to reduce scale; monitor chlorides with stainless.

-

Drain for freezes. If sub-zero risk exists, fully drain or use compatible antifreeze.

Data Discipline: Decide Clean vs. Open with Numbers

Track three KPIs per exchanger:

-

ΔP across plate pack at standard flow.

-

Approach temperature (hot-out minus cold-in) for thermal effectiveness.

-

Energy per unit duty (kWh per MWh transferred), if available.

Set action thresholds (e.g., ΔP +20–30% from baseline or approach temp +2–3°C) to trigger CIP. If KPIs don’t recover after CIP, schedule an open-and-clean with inspection. Document the results to calibrate future thresholds.

Recommended Spares & Tools for Faster Turnarounds

-

Full gasket set (OEM) + ring gaskets for ports.

-

Tie-bolt nuts/washers (select spares); high-temp anti-seize/grease (for bolts only).

-

Dye-penetrant kit for pinhole checks; nylon brushes; pH strips; plate-safe descaler & neutralizer.

-

Measuring tools (calipers/tapes) for plate-pack dimension.

-

Spare plates in services with known erosion/corrosion risk.

Who Should Service Your PHE?

If you don’t have an in-house PHE specialist, work with a service partner that can audit ΔP and approach trends, match gasket polymers to duty, and regasket to OEM dimensions. For India-based buyers and operators, explore SRJ Industries for service and spares, and their SRJ Heat solutions for plate/gasket support and maintenance programs.

Conclusion

The most effective “PHE maintenance program” is a short, repeatable checklist executed on schedule—and measured. Start with daily logs, prefer CIP, protect and store gaskets properly, assemble to the plate-pack dimension, and hydrotest before you go live. The result is fewer emergencies, predictable outages, and a longer asset life at a lower total cost of ownership. If you need help tailoring a maintenance plan or sourcing OEM-grade plates and gaskets, speak to SRJ Industries or explore SRJ Heat.

FAQs

Q1. How often should a PHE be cleaned?

By condition, guided by ΔP and approach temperature. In scaling duties, expect 6–12 months; clean, closed-loop duties can run longer. Start with semi-annual checks and adjust.

Q2. CIP or manual cleaning—what’s cheaper long-term?

CIP is usually faster and gentler on gaskets. Open only if CIP doesn’t restore KPIs or when inspection is required.

Q3. Which chemicals are plate-safe?

Use alkaline for organics; citric/sulfamic/phosphoric for carbonate scale/rust. Avoid chlorides on stainless; follow OEM recommendations and neutralize/rinse thoroughly.

Q4. Why do gaskets leak after reassembly?

Common causes: dirty grooves, twisted/stretched gaskets, under/over-tightening, or wrong plate order. Close to the OEM “A” dimension and hydrotest before service.

Q5. What extends gasket shelf life?

Store cool, dark, dry, sealed, away from UV and ozone sources (motors/welders). Track manufacturing dates; use FIFO.

Q6. Can erosion really be a problem in PHEs?

Yes—grit can sandblast inlets/corrugations. Add strainers, keep velocities within OEM limits, and inspect for shiny wear patterns.