Precision-Engineered Heat Exchanger Plate Solutions for Industrial Performance

SRJ Heat Exchangers India Pvt. Ltd. is a specialized manufacturer and supplier of heat exchanger plate solutions, delivering precision-formed plates and compatible sealing components engineered for demanding industrial processes.

With years of hands-on manufacturing experience and a strong engineering foundation, our heat exchanger plates are designed to ensure efficient heat transfer, stable plant operation, and long service life, helping industries reduce downtime and improve overall process reliability.

Heat Exchanger Plate Engineered for Real IndustrialConditions — Not Just Catalog Specifications

In demanding industrial environments, heat exchanger plate performance is tested under real pressure, fluctuating temperatures, aggressive media, and continuous operating cycles, not controlled laboratory assumptions.

At SRJ, every heat exchanger plate solution is developed with actual operating conditions in mind, ensuring consistent thermal performance, mechanical reliability, and long-term stability well beyond commissioning.

Our expertise covers:

- Thermal design accuracy

- Material compatibility

- Pressure & temperature limits

- Maintenance accessibility

- Lifecycle cost optimization

Request a Customized Heat Exchanger Plate Solution

Whether you are replacing an existing unit or planning a new installation, our technical team helps you select the right heat exchanger plate configuration based on real operating requirements, including:

- Process fluid characteristics

- Flow rate and temperature range

- Operating pressure conditions

- Space and layout constraints

- Industry-specific compliance needs

Share your requirement and receive engineering-backed heat exchanger plate recommendations, not generic quotations.

Why Process Industries Choose SRJ Heat Exchanger Plate Solutions

Consistent quality across heat exchanger plates, sealing components, and spares

OEM-compatible heat exchanger plates designed for precise fit and reliable operation

Fast turnaround supported by dependable technical guidance and application support

Our approach is not volume-driven — it is performance-focused heat exchanger plate manufacturing built for real operating conditions.

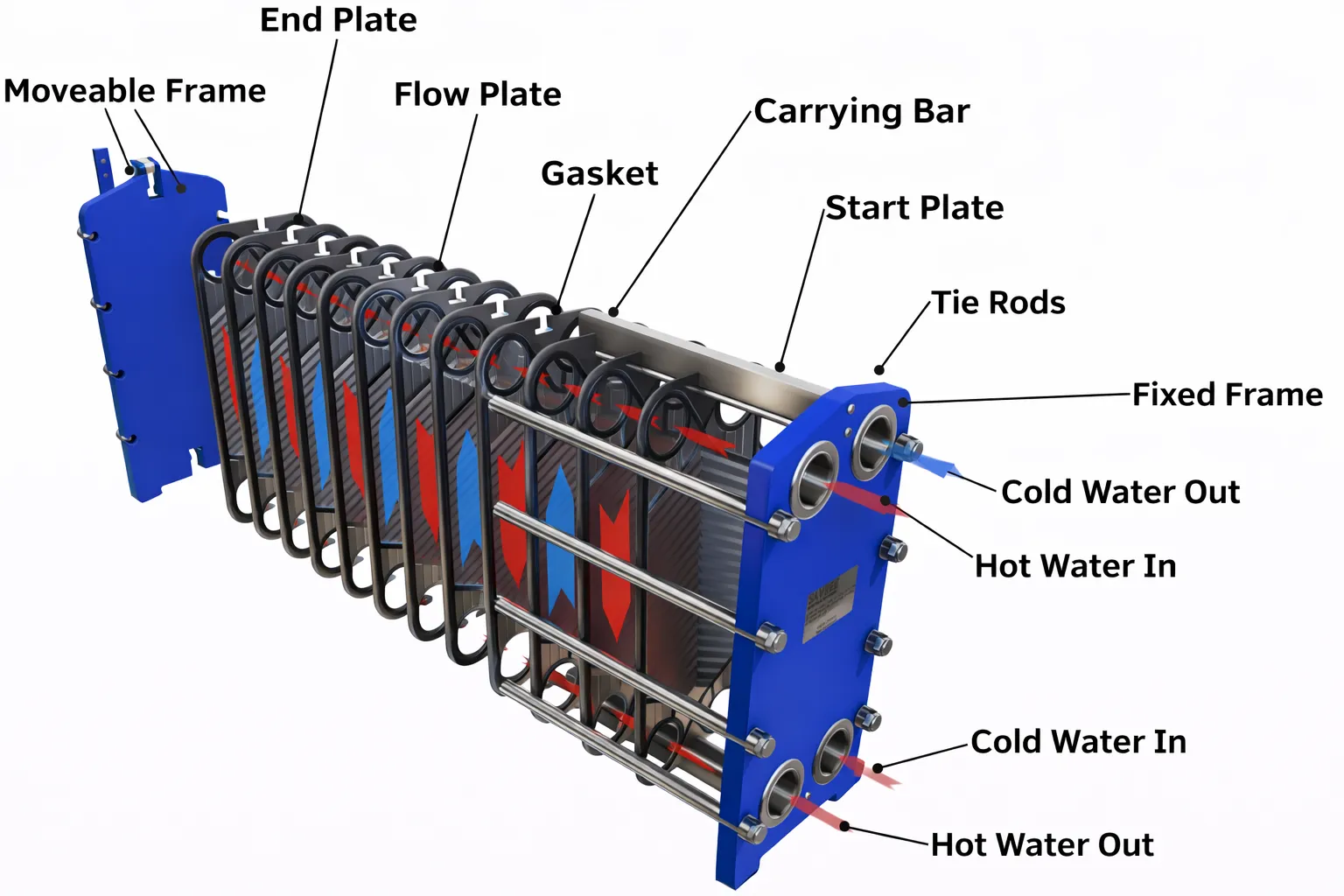

Heat Exchanger Plate

The heat exchanger plate is a critical component designed to deliver efficient heating, cooling, and heat recovery across industrial processes. Its precision-engineered surface geometry enables maximum heat transfer within a compact assembly, making it suitable for modern process plants where space, efficiency, and reliability matter.

Key Advantages:

- High thermal performance through optimized plate surface patterns

- Compact and modular design supporting flexible system layouts

- Easy inspection, cleaning, and capacity enhancement

- Reduced energy consumption with stable long-term operation

Common Applications:

Food & beverage processing, dairy, pharmaceuticals, chemicals, HVAC systems, utilities, and general process industries.

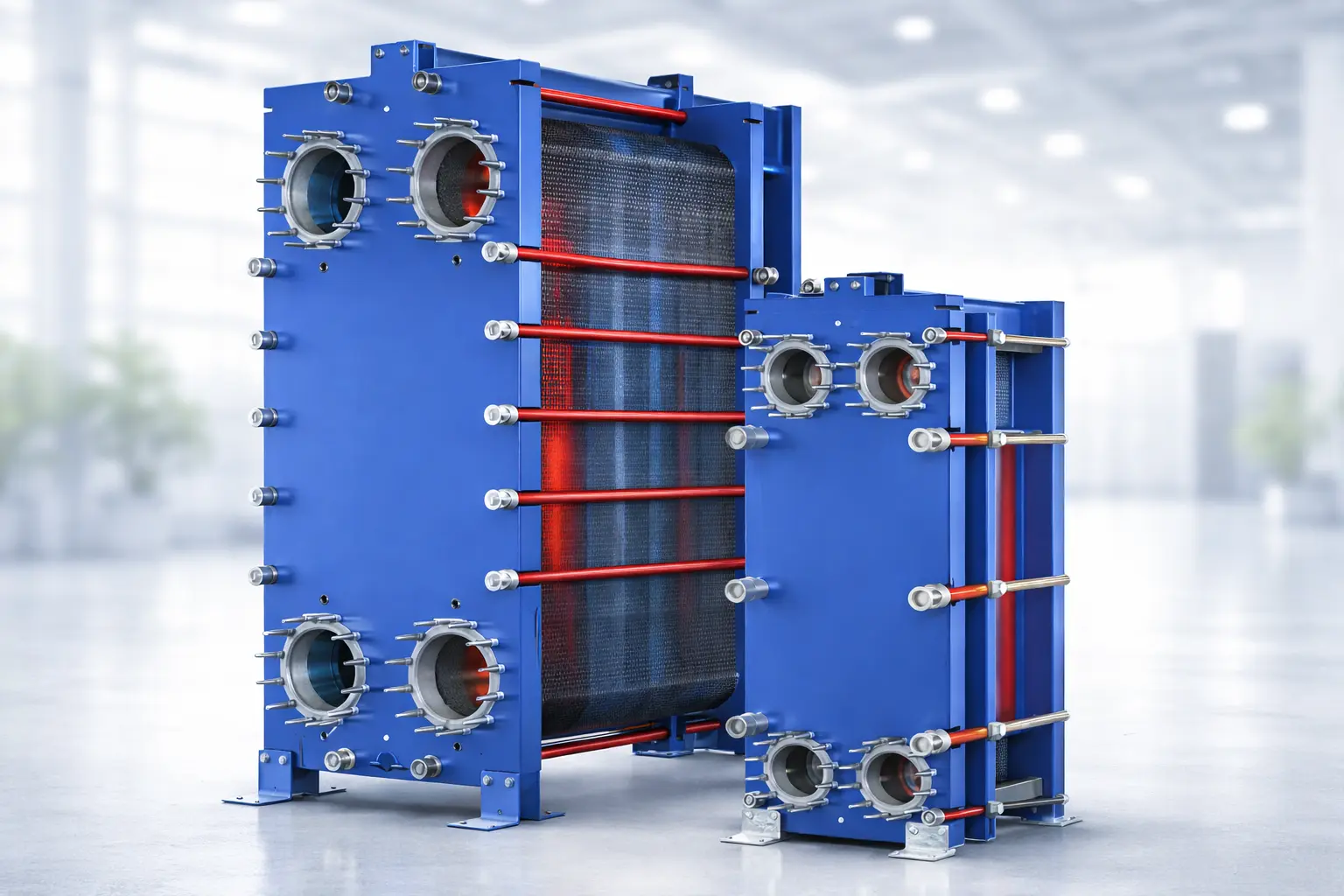

Heat Exchanger Plate in Plate and Frame Configuration

The heat exchanger plate used in plate and frame configurations provides flexibility where operating conditions vary or future capacity expansion is required. Individual heat exchanger plates can be added or removed to match changing thermal and process demands without replacing the complete unit.

Why Industries Prefer This Plate Design:

- Modular plate arrangement supporting scalable capacity

- Precise temperature control through optimized plate patterns

- Easy gasket replacement and plate accessibility

- Reduced maintenance time and improved operational uptime

Brazed Plate Heat Exchanger

The heat exchanger plate used in brazed construction is designed for compact, fully sealed applications operating under high pressure and high temperature conditions where external sealing elements are not required. These heat exchanger plates are permanently bonded to deliver stable thermal performance in demanding duty cycles.

Key Advantages:

- Compact and lightweight plate construction

- High mechanical strength under pressure

- Efficient heat transfer through optimized plate geometry

- Lower installation and lifecycle cost

Typical Uses:

Refrigeration systems, chillers, heat pumps, oil cooling, and district heating applications.

Heat Exchanger Plate for Welded Construction

The heat exchanger plate designed for welded construction is suitable for applications involving aggressive media and extreme operating conditions. These heat exchanger plates are permanently joined to eliminate leakage points while maintaining reliable heat transfer performance under high pressure and temperature.

Features:

- No elastomer seals, enabling operation with aggressive fluids

- Excellent chemical and corrosion resistance

- Suitable for high-pressure and high-temperature processes

- Extended service life with stable long-term performance

Shell and Tube Heat Exchanger

The shell and tube heat exchanger remains a preferred choice for heavy-duty industrial processes requiring robust mechanical design.

Key Advantages:

- Handles high pressure and temperature

- Flexible material selection

- Proven reliability in continuous operations

- Low installation cost

Industries Served:

Oil & gas, petrochemical, power generation, chemical processing.

Heat Exchanger Plate for Wide Gap Applications

The heat exchanger plate designed for wide gap applications is engineered to handle fluids containing fibers, suspended solids, or high-viscosity media that can restrict conventional plate channels. These heat exchanger plates allow smooth flow while maintaining effective heat transfer under challenging process conditions.

Ideal For:

- Sugar processing and viscous media handling

- Pulp and paper applications

- Wastewater and effluent treatment

- Bio-based and solids-laden process streams

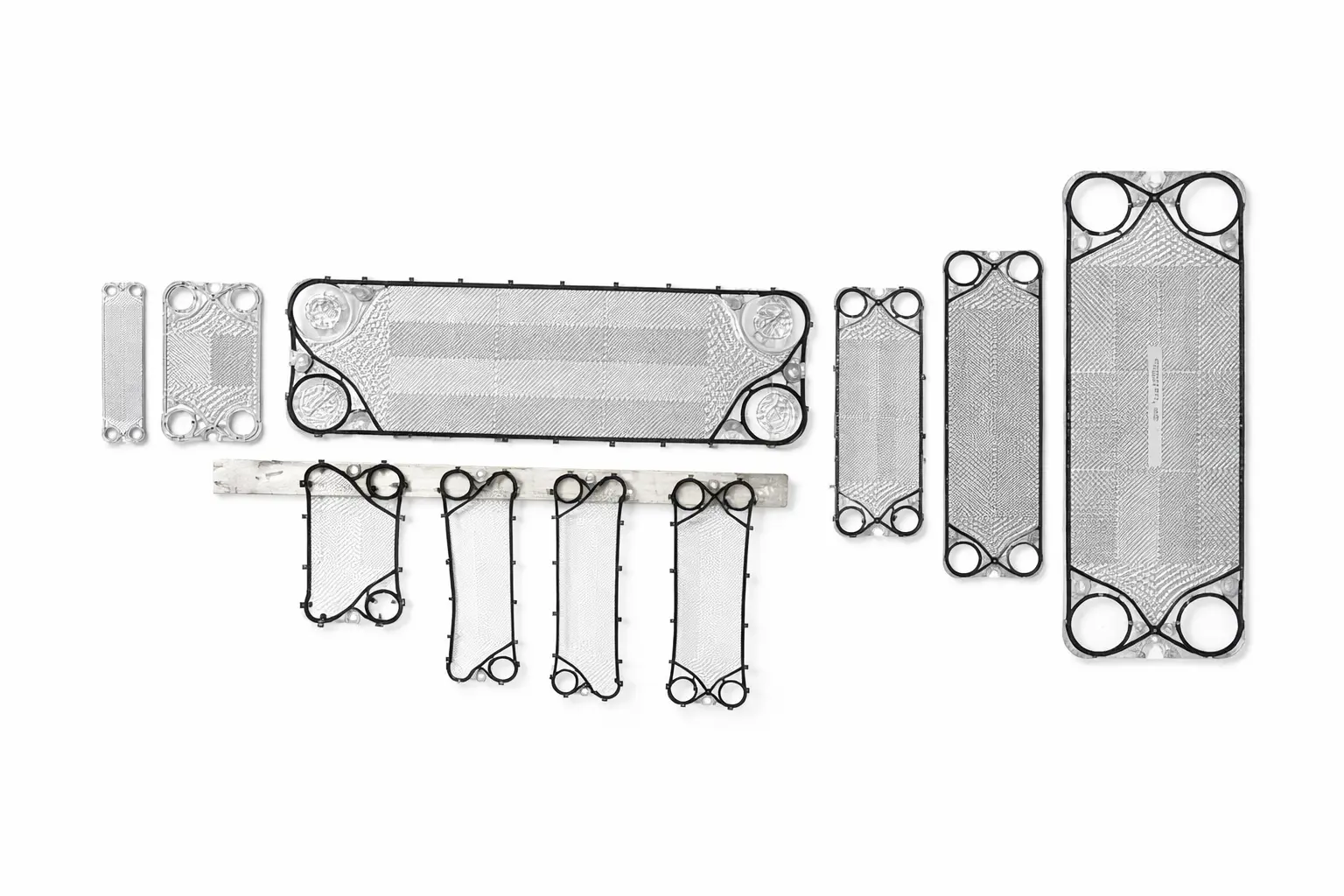

Heat Exchanger Plate – Precision Manufactured for Performance

Heat transfer performance depends heavily on heat exchanger plate quality. Our heat exchanger plates are manufactured with strict dimensional accuracy to ensure precise alignment, uniform flow distribution, and consistent thermal efficiency across operating conditions.

Available Heat Exchanger Plate Materials:

- Stainless steel grades for general industrial applications

- Titanium heat exchanger plates for corrosive media

- Special alloy plates for demanding process environments

Each heat exchanger plate is inspected for form accuracy and surface integrity to deliver reliable and repeatable thermal performance over long service life.

PHE Gaskets – Reliable Sealing for Heat Exchanger Plate Systems

As experienced PHE gasket manufacturers and suppliers, we produce PHE gaskets engineered to deliver reliable, long-lasting sealing performance under continuous thermal cycling and demanding industrial conditions. Our PHE gaskets are precisely designed to match heat exchanger plate profiles, ensuring leak-free operation and consistent system performance.

PHE Gasket Material Options:

- NBR PHE gaskets for oil-based and hydrocarbon fluids

- EPDM PHE gaskets for water and food-grade applications

- Viton PHE gaskets for high-temperature and chemical resistance

- Specialized PHE gasket compounds for custom requirements

Our role as a trusted PHE gasket supplier ensures secure fitment, easy installation, and extended service life across a wide range of heat exchanger plate applications.

OEM-Compatible Spare Parts for Heat Exchanger Plate Systems — Without Compromising Quality

SRJ supplies OEM-compatible heat exchanger plates and PHE gaskets engineered to match original specifications with high precision. As a reliable heat exchanger plate and PHE gasket supplier, we ensure accurate replacement without affecting system performance.

Our OEM-compatible components are matched for:

- Dimensional accuracy and plate thickness

- Port alignment and flow distribution

- Plate pattern geometry

- Gasket groove profile and sealing fit

This ensures seamless replacement of heat exchanger plates and PHE gaskets without any modification to existing frames or assemblies, supporting long-term operational reliability.

How We Deliver High-Performance Heat Exchanger Plate Solutions

Engineering & Manufacturing Process Built for Real Operating Conditions

1. Requirement Evaluation

We begin by understanding actual operating parameters to define the right heat exchanger plate configuration, including process fluid, temperature range, pressure limits, and duty cycle.

2. Thermal & Mechanical Design

Our engineers design heat exchanger plates with optimized flow patterns to achieve consistent heat transfer performance while maintaining mechanical strength under real plant conditions.

3. Material Selection

Each heat exchanger plate material is selected based on fluid compatibility, corrosion resistance, temperature limits, and long-term operating reliability.

4. Precision Manufacturing

Heat exchanger plates are manufactured under controlled processes to ensure dimensional accuracy, uniform plate geometry, and reliable sealing interface compatibility.

5. Quality Testing & Dispatch

Every heat exchanger plate and PHE gasket undergoes inspection and performance checks before dispatch to ensure dependable operation from day one.

Industries We Serve

Dairy & Breweries

Pharmaceutical Manufacturing

Chemical & Petrochemical Plants

HVAC & Refrigeration Systems

Power Generation

Marine & Offshore

Sugar, Ethanol & Bioenergy

Our solutions are trusted wherever process reliability and thermal efficiency are critical.

Get Expert Support for Your Heat Exchanger Requirement

If you are looking for efficient heat exchangers, reliable spare parts, or engineering-backed recommendations, connect with our team today.

📩 Submit your enquiry and receive a solution designed for performance, durability, and operational confidence.

Our Clients

Join a network of trusted partners who rely on our quality solutions.

Our client logos represent our commitment to excellence and strong collaboration.